Delta chooses Vibrotech’s Ink Refill Technology

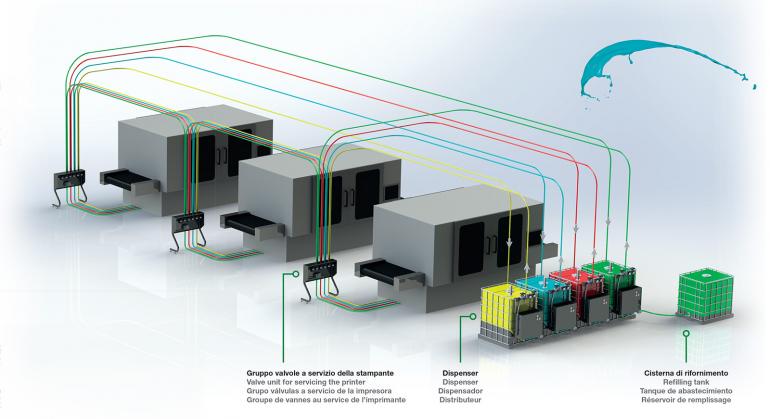

The Brazilian manufacturer will adopt a new automatic system for storing, mixing and feeding inks to digital printers at its Rio Claro facility.

Delta Industria Ceramica, one of Brazil’s largest ceramic and porcelain tile manufacturers, has chosen Vibrotech’s Ink Refill technology for storing, mixing and feeding inks to digital printers at its Rio Claro facility.

The system manages eight colours, mixing and filtering them constantly and then transferring them fully automatically to the eight digital printers on the production lines via a dedicated valve stand for each of the printers. The system also features closed-circuit recirculation for each individual colour.

The system is expandable without limits in terms of both the number of colours and the number of printers to be managed.

The equipment supplied by Vibrotech also includes automatic ink level control and a system for refilling the 1300-litre containers by means of automatic pumps. A QR Code is applied to each ink dispenser and the pump operation is disabled if it differs from the code assigned to each colour, thereby preventing colour contamination. Vibrotech will perform mechanical and electrical installation and testing of the system, which is scheduled to take place by the end of the year.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks