High-performance technologies from BMR for the European market

BMR’s heavy clay division continues to garner recognition amongst national and international brick and tile manufacturers who appreciate the outstanding quality of its technologies backed up by rapid and effective customer support.

BMR’s heavy clay division, considered a strategic asset for the overall growth of a company that already holds a leadership position in the ceramic finishing technology sector, continues to garner recognition amongst national and international brick and tile manufacturers who appreciate the outstanding quality of its technologies backed up by rapid and effective customer support.

A number of European brick and tile producers in countries such as Germany, Slovakia, Belgium, Poland and the UK have recently chosen BMR technology for their expansion projects, allowing them to make significant improvements in both efficiency and production quality and further solidifying BMR’s reputation as a dependable and effective partner for the industry.

Europe’s big names choose Italian-made technology from BMR

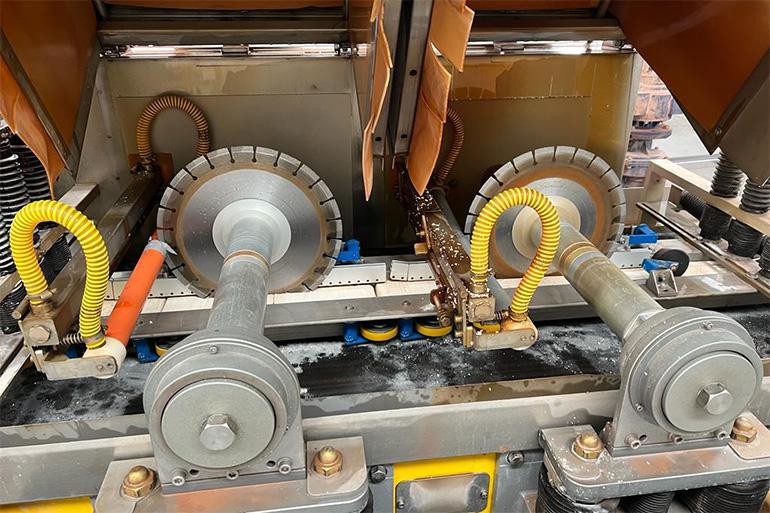

Röben, a German producer of bricks and brick slips for facades, clay roofing tiles and fine stoneware for commercial and industrial floors, has opted for a BMR brick-cutting machine used to cut corners for use as cladding. As a result of this investment, the company has improved its feed rate to 1.2 metres per minute and output to 17 pieces per minute.

Rustique, a Slovakian company with more than 20 years’ experience in the production of 100% green brick slips, has installed two complete lines equipped with cutting, drying and sorting machines complete with manual packing solutions for a total production of 80 brick slips per minute.

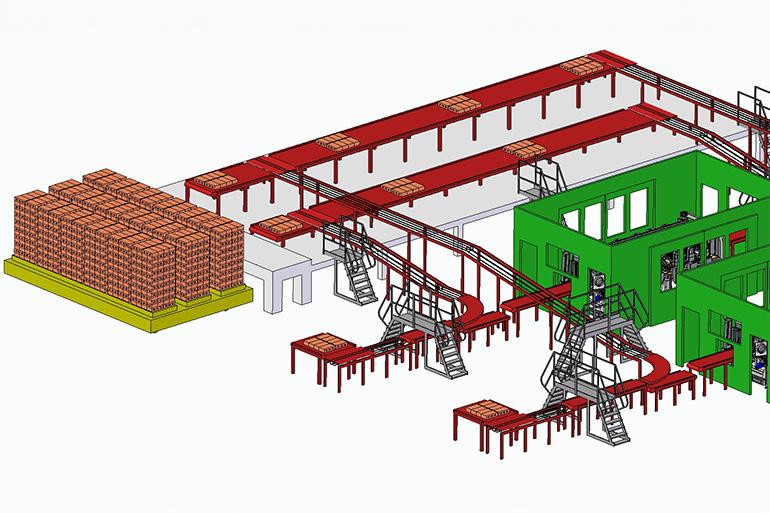

As part of another major order, BMR has supplied an upgraded finishing and packaging line to Vandersanden, a Belgian manufacturer that is committed to improving the sustainability of its production activities. Equipped with an automatic sorting system, the high-performance line produces 80 rectified brick slips per minute.

Ceramika Podkarpacka, a leading Polish clay block manufacturer, has installed a high-performance Ecobrick dry squaring line for grinding hollow blocks. The new machine guarantees a high level of performance and a high-quality finish with perfectly parallel sides. The use of Ecobrick has enabled the company to achieve a productivity of 32 pieces/minute of the 250x250x325 mm block with excellent surface finish characteristics.

Finally, two high-performance finishing and packaging lines will soon begin operation at the site of the UK’s leading brick manufacturer, with expected outputs of 110 pieces/minute for grinding alone and 50 pieces/minute for grinding and kerf cutting.

The positive feedback received from customers confirms BMR’s role as the preferred partner for companies seeking to expand their business with modern, safe and efficient technologies.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks