Panariagroup adopts three new complete squaring lines from Ancora

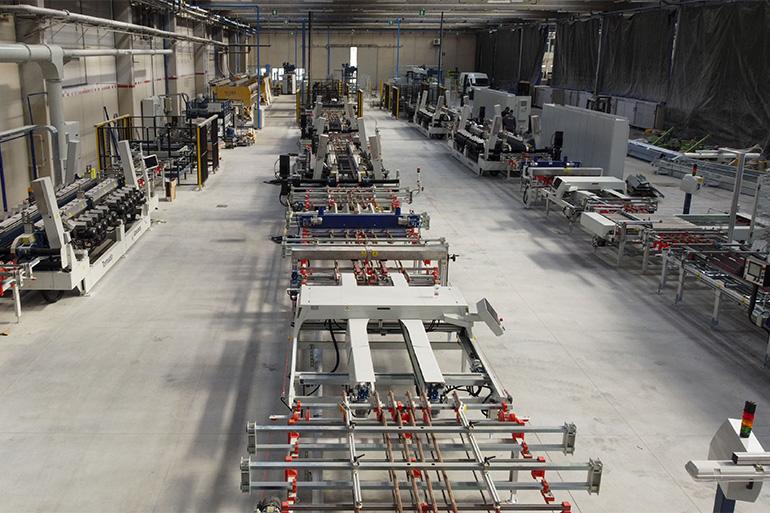

Panariagroup has installed latest-generation Tornado end-of-line technology at its factory in Toano.

Following record fast installation, the three new Tornado dry squaring lines from Ancora (Gruppo B&T) chosen by Panariagroup for its Toano (RE) facility are now fully operational. Capable of handling sizes up to 120x120 cm and 90x180 cm with thicknesses of up to 20 mm, these latest-generation technologies are complemented by Arko, Kros and Combicut score-and-snap cutting machines.

The three fully automated lines can be operated simultaneously by a single operator in a simple and intuitive fashion thanks to the new EASY-STEP software, which provides step-by-step operator guidance and continuous machine and production status updates.

Ideal for large-scale production, Tornado is extremely robust and stable and constructed from the highest quality materials. When positioned at the kiln exit, it improves the efficiency of the squaring process, significantly reduces logistical and management costs and increases productivity to up to 20,000 square metres/day. It is also equipped with a new laser system capable of measuring and controlling the grinding process in real time and taking action autonomously in the event of errors, thereby guaranteeing continuous accurate removal over time. Tornado is also environmentally friendly thanks to its reduced energy consumption, lower operating costs and simpler and cheaper maintenance.

As well as ensuring maximum productivity, the new lines will allow Panariagroup to manage all products without the need for external assistance.

“We are very pleased to be working once again with Panariagroup on a project that, in our opinion, represents the ultimate in end-of-line technology,” said Gruppo B&T’s Chairman and CEO Fabio Tarozzi. “Panariagroup continues to demonstrate to the world its leadership position in the production and distribution of ceramic floor and wall tiles. We are proud to accompany it on this journey.”

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks