From analogue to digital, the pursuit of quality in the development of decoration

First launched in 2011, the Creadigit digital printing technology recently celebrated its first 10 years on the market, confirming System Ceramics’ leadership in the field of digital decoration and printing.

Creadigit was officially launched in 2011, but System Ceramics’ R&D laboratories had long been working on a digital solution that would enable the company to continue its success in the field of decoration.

Right from the start, it invested several million euros in the purchase of materials for machine testing, in building clean rooms, laser cutting areas and assembly and welding centres, in developing hardware and in providing the best possible support for its laboratory. Still today, the laboratory remains the cornerstone of an all-round digital service capable of providing customers with expert support in solving problems and optimising performance.

To tackle the transition from analogue to digital, System Ceramics teamed up with Dimatix with the shared goal of creating a dedicated printhead for the ceramics sector exploiting both companies’ experience in their respective fields.

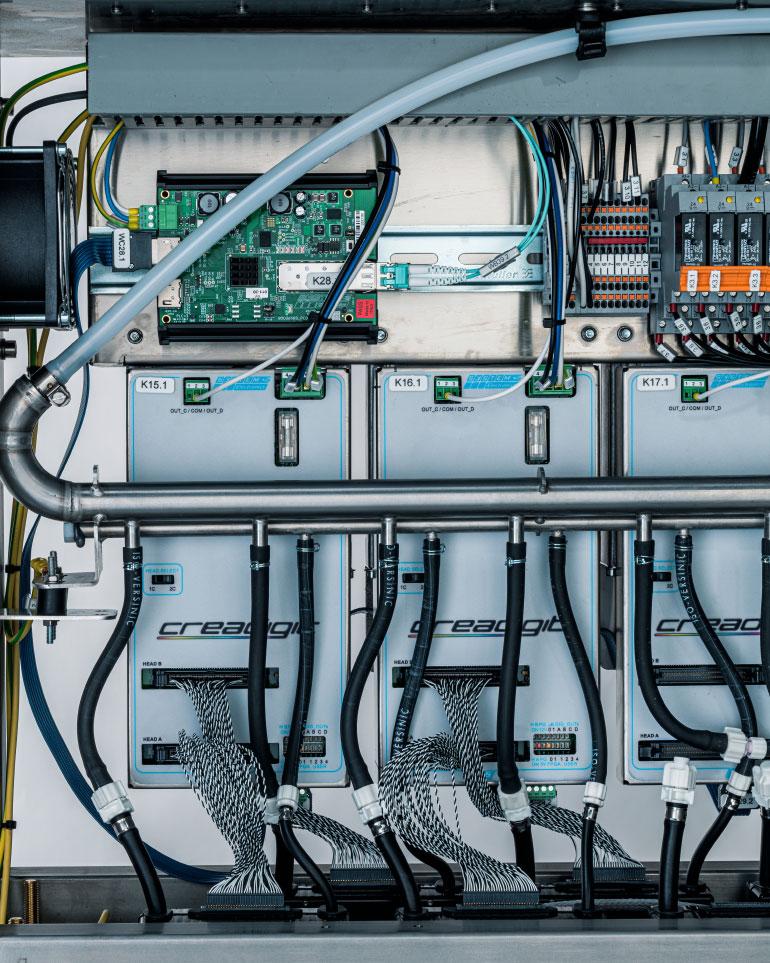

These joint efforts led to the first ever Dimatix printhead with nozzle plate recirculation. This innovative printhead served as the starting point for the development of a technology that is fully controlled by System Ceramics and its business units, from electronic and electrotechnical aspects through to software development and chemical and physical characteristics.

Creadigit, a 100% System Ceramics technology

Creadigit is designed and developed entirely in-house by System Ceramics, which works alongside product managers in every step of the tile decoration development process, from organising the sequence of different resolutions, types of printheads, inks and materials through to customising the process and determining the precise design of the end product.

Almost 60 different versions of Creadigit have been developed over the last 10 years to cater for the many different needs of the market. This has enabled Creadigit to establish itself all over the world and to provide an effective response to the different production requirements.

Renowned for its exceptional levels of flexibility and versatility, Creadigit is the ideal solution for companies requiring high levels of aesthetic performance in the production of large sizes (the Creadigit XXL and Creadigit BS versions are especially popular for these applications). However, it is equally appealing to producers of more traditional sizes and solutions due to the fact that it is continuously updated according to the latest trends in the ceramic industry. Creadigit has evolved in step with the aesthetic and qualitative changes in the field of ceramic surfaces and has responded to the latest developments with various kinds of upgrades.

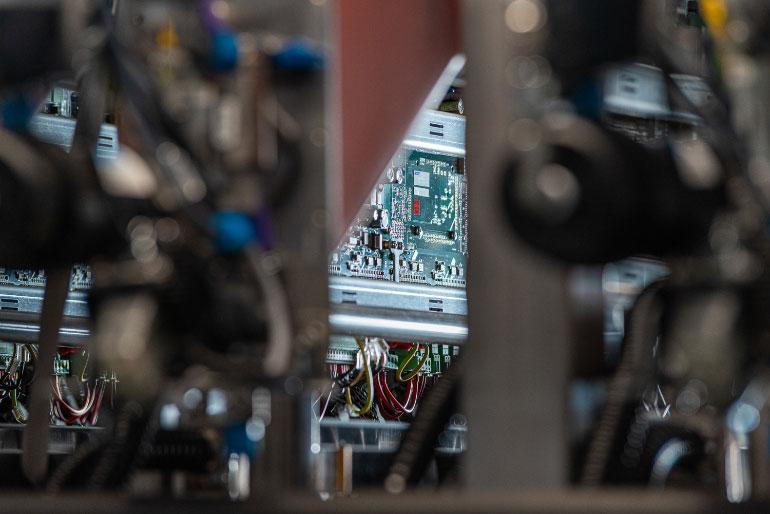

Collaboration between the various System Ceramics divisions, in particular with System Electronics, brought about a revolution in the field of digital decoration: Creadigit Infinity, a printer with unprecedented computing power based on the latest-generation CoreXpress platform, the processing unit (one for each bar) that governs all operations. The information needed to reproduce the image on the ceramic surface is processed and managed in real time. And the presence of 12 or more bars, each of which can be fitted with printheads from different manufacturers and with different resolutions and laydown capacities, coupled with the possibility of using a resolution of up to 600 dpi makes for an enormous range of graphic effects.

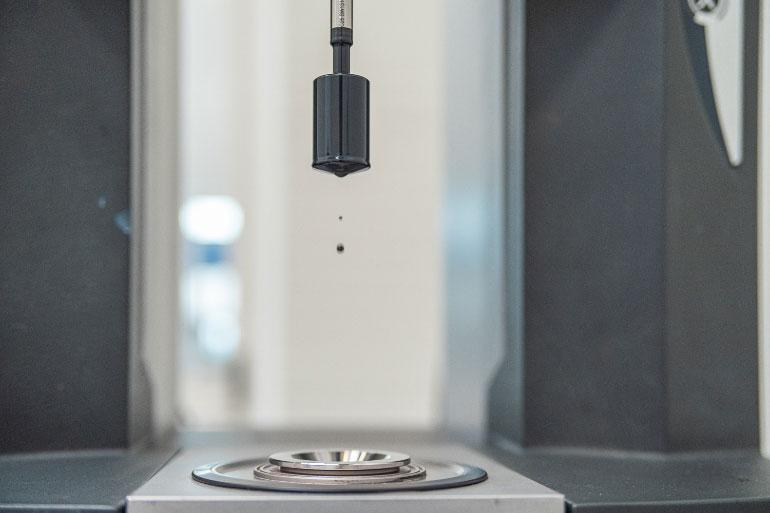

Automation and digitalisation are the latest steps in the transition towards Industry 4.0, and with this in mind System Ceramics has further raised the standards of decorative excellence with Creavision e-View. An even more comprehensive and high-performance self-regulating vision and quality control system, it employs new full-view fixed cameras to achieve a field of vision that extends over the entire roller. This results in higher precision and print quality, greater speed, improved productivity with minimal manual intervention, and no less importantly a significant reduction in production costs.

The future

There are several keywords that describe the future evolution of Creadigit technology. One of these is flexibility, a distinctive characteristic not just of Creadigit but also of the team that has developed the technology. Flexibility is also important in terms of the freedom of development needed to respond to the most important trends in lean manufacturing while continuing to guarantee the excellence of Italian-made products from the point of view of quality, functionality and aesthetics. Another keyword is sustainability and the development of increasingly eco-friendly solutions to protect people and the environment. These include energy-saving measures, the introduction of new vision systems to reduce the quantity of ink used, new digital and automation upgrades, process optimisation and ongoing research into a new water-based printing method.

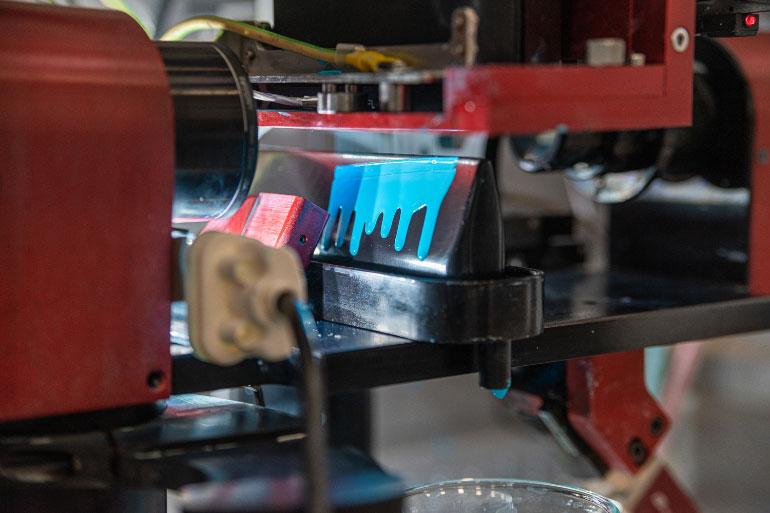

As for products, companies are constantly in search of the highest levels of customisation to enable them to stand out in the high end of the market, which is no longer determined solely by colour but also by material characteristics. Glossy, metallised and 3D effects are new aspects of digital printing that are defining the future of Creadigit.

For System Ceramics, freedom of development also means introducing digital printing into new markets, such as glass, where it is already present with Creaglass, and textiles. At the same time, it is carrying out research in the ceramic sector with the aim of further developing the entire glazing line in anticipation of pre- and post-printing applications.

This will require the use of multiple technologies to achieve full digitalisation. The first is Genya software, which instructs the machines on the sequence of applications to be carried out, allowing the operator to easily control all possible combinations online without having to manage each individual unit.

Another important development is the Eye-tron vision system, an autonomous intelligence system that uses video cameras to extract geometric and surface information and is used by Creadigit to fine-tune the printing process and achieve perfect synchronisation between the design and the ceramic substrate. Eye-tron further improves on the already exceptional levels of control offered by System Ceramics’ Qualitron vision system, which uses Creasync software to improve the process of controlling and acquiring graphic images for the detection of surface defects, thereby eliminating all the effort of physical sampling.

These technologies, which interconnect as part of an IoT ecosystem, complete the process and help client companies improve their competitiveness in the international ceramic industry.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks