Media for digital glazing with water-based glazes and engobes

Lamberti presents the Printojet S series of additives which ensure optimal surface tension and rheology, as well as good binding power and lubricating properties to guarantee a high-quality surface in terms of spreadability and homogeneity.

Following a lengthy period of experimentation, the digital application of water-based glazes and engobes is now becoming a widely established technique in the ceramic industry. In this process, on-demand technology is used to apply glaze droplets to the tile surface while controlling the machine’s jetting pressure.

Machine pressure and glaze and engobe viscosity play a key role in the successful adoption of this technology at an industrial level.

The role of stabilising the droplets and controlling the surface tension is performed by the medium, which directly influences the interaction between the liquid phase of the glaze and the tile surface.

There is a direct relationship between the spreadability of a glaze and the interaction between the glaze droplets and the substrate. Achieving the correct working parameters is essential for ensuring the compactness and spreadability of the glaze layer.

The choice of the right additive/medium is essential for achieving the desired surface quality and requires a knowledge of both production needs and chemical additives.

The Printojet S series ensures optimal surface tension and rheology, as well as good binding power and lubricating properties. Surface tension is closely related to the wettability of a given surface by a liquid. In this case, it describes the tendency of glaze droplets to spread out over the substrate.

The correct values of glaze surface tension (determined by the Printojet S surfactants) therefore guarantee a high-quality surface in terms of spreadability and homogeneity.

The important role of viscosity

Low-viscosity glazes and engobes (applied using airless techniques) have always been popular because they can be used over a wide range of densities and viscosities.

In digital glazing, these working parameters and the dosage of medium must be maintained within a narrower range.

In particular, the viscosity values must be kept strictly constant to ensure stable production. Once this has been achieved, the technology brings numerous advantages including glaze optimisation, reduced waste, no need for inline extraction systems and a significant reduction in washing water usage and operator intervention.

The glazes and engobes are milled with water and Printojet S at dosages of between 3% and 5%. Alternatively, Printojet S can be added after mill discharge. Working densities are normally between 1350 and 1500 g/l with a viscosity range of 11-15 sec. with a 4 mm Ford cup.

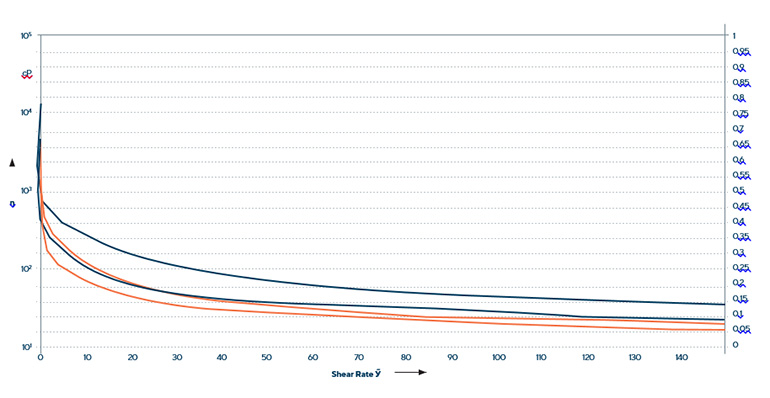

The rheogram below shows the flow curves for two engobes with the same viscosity (12 sec. with 4 mm Ford cup). The graph shows how viscosity changes (y-axis) with shear rate (x-axis).

The engobe represented by the blue curve can be successfully applied using the digital glazing machine, whereas the engobe corresponding to the orange curve cannot guarantee correct application.

Rheological diagram of viscosity against shear rate

Blue Curve: Engobe with 3% Printojet S (density 1450 g/l, viscosity FC 4 mm 12 sec.)

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks