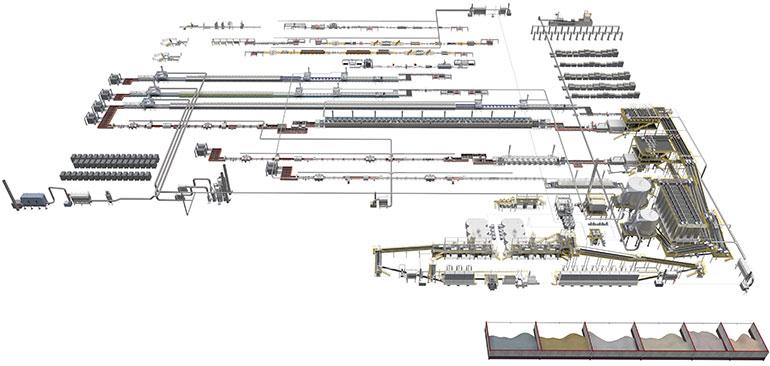

Digitalization and sustainability are the two key drivers that merge with Sacmi’s wider plant engineering logic. The goal: to maximize productivity and versatility as part of a new manufacturing approach that focuses on environmentally and socially sustainable production, but without compromising on quality or aesthetics.

“Tecna 2022 is the place to meet customers face-to-face again and to discuss new and more ambitious projects,” said Sacmi’s chairman Paolo Mongardi when commenting on his company’s participation in the 27th edition of the international exhibition in Rimini.

This edition of the show will focus on the opportunities offered by the ecological and digital transition, two ambitious goals for which Sacmi aims to develop unprecedented solutions even compared to current market best practices as part of its technological and plant-engineering vision. Maximum productivity and versatility continue to be the main objectives, but with a new approach to the factory that focuses on the environmental and social sustainability of production without compromising on quality or aesthetics.

Growth in global demand for ceramic products

Last year’s surge in investments in the tile industry led to an all-time sales record for Sacmi (99% growth in machinery sales alone).

“The market continues to display strong demand for ceramic products, a trend we are seeing on a global scale despite new challenges relating to raw material availability and energy costs,” explains Matteo Federici, General Manager of the Tiles Business Unit at Sacmi.

This is why it is necessary to focus more strongly than ever on the two drivers that are capable of restoring competitiveness to the sector while fuelling new product development: sustainability and digitalisation, which in reality are two sides of the same coin.

“The aspect of digitalisation that we are presenting at Tecna 2022 is primarily related to process control and plant integration, two areas in which Sacmi offers a wide range of innovations, particularly in terms of new product development and market launches,” explains Federici.

Alternative fuels, energy recovery, waste reduction, and optimised process management as part of the circular economy are further aspects of a ceramic plant which, according to Federici,

“is designed to work organically, synergistically, according to a single digital process governance architecture” and with complete solutions aimed at “improving the energy balance of the factory, starting with the integrated heat, flue gas and emissions recovery systems in which we are the world leaders”.

Technology at the service of humans in the new “lights-out factory”

While environmental sustainability is important, so too is social sustainability in terms of the safety of the people who work on a daily basis in the factory, in contact with products. Is it possible to relaunch an idea of quality and competitiveness – craftsmanship even – in a “lights-out” factory?

“As a producer of ceramic sanitaryware technology, we have for years been working alongside both industry multinationals and high-end manufacturers who choose to enhance their product quality and production efficiency,” notes Daniele Coralli, General Manager of Sacmi’s Whiteware BU.

So alongside advanced automation in terms of casting, glazing and robotic handling, Sacmi’s offering now also includes a new solution that has been well received by leading market players and is being showcased at Tecna 2022. Called Sacmi Robot Clean, it is the final step in the sanitaryware white finishing automation process and brings advantages in terms of both the aesthetic quality of the product and the health of operators, who are no longer exposed to potentially hazardous crystalline silica dust.

“We are seeing a market that is particularly reactive to external pressures,” explains Coralli. These include increases in transport and energy costs, which “in advanced markets are driving investments in new projects focused on the concepts of sustainability and automation, all of which are factors that reward our technology proposition”.

“Uncompromising quality” and profitable sustainability

Returning to the field of tiles and surfaces, at Tecna 2022, in Hall B1, Sacmi will be previewing a number of solutions developed with “uncompromising quality” and profitable sustainability for its partners in mind.

As Davide Trombettini, Sales Director at SACMI’s Tiles BU, explains, here, the technologies needed to create new products, especially those inspired by natural stone, are complemented by specific proposals designed to ensure repeatability, sustainability and cost-effectiveness in versatile batch management”.

One of the most important of these is the PCR2120 version of Continua+, the smartest machine in its category. Designed for very high speeds (up to 10 metres per minute), it also has reduced dimensions, unsurpassed flexibility in handling both slabs and standard tile sizes, and the lowest levels of specific consumption on the market.

Alongside this is a complete range of solutions for the alternative management of thermal processes based on the use of “clean” fuels, such as the new hydrogen burners for kilns and dryers, while at the same time exploiting all the advantages of integrated recovery, which enables entire machines or departments (especially dryers) to be operated entirely without the need for fuel. Another issue concerns process waste, with full recovery of the already small volumes of scrap and the reduction of reprocessing costs.

Added to this are high-speed sorting systems, again designed for efficient management of small batches and optimised production flows in a “pull” logic with order feedback onto the process.

“At the same time, service is an increasingly important aspect of our offering,” concludes Trombettini. “Tecna 2022 will be an opportunity to propose new high added-value service packages supporting customers in all stages of the production process, from design to product, from predictive maintenance to spare parts.”

The innovative booth layout will offer visitors an immersive journey through the ceramic plant and the opportunity to discuss every single aspect of the process. As well as getting a close look at the technologies on display, they will be able to physically move around the advanced plant, selecting points of interest and discussing individual value propositions with the team of specialists on hand.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks