BMR brings the evolution of dry technology to the United States

BMR will exhibit at Coverings (booth no. 4752), showing the latest development of ceramic tile finishing machinery.

BMR is ready to fly to the United States on the occasion of Coverings 2023, the main ceramic and natural stone fair in North America scheduled from 18 to 21 April at the Orange County Convention Center in Orlando, Florida.

An unmissable appointment for the company from Scandiano (Reggio Emilia, Italy), which will allow customers and visitors to experience the high level of performance achieved by the ceramic tile finishing processes, guaranteeing considerable added value to the finished product. All this in a country, the United States, where BMR has installed over 40 systems dedicated to the finishing (cutting, polishing, lapping and squaring) of the entire range of tile sizes, from the smallest ones (100x100 mm) up to the large slabs and panels (1800x3600mm). The snapshot of the company's expertise gained in over 50 years of activity, is characterized by professionalism, quality, efficiency, farsightedness and continuous investments resulting from incessant research work.

The innovative evolution of the BMR Dry technology will confirm the Italian company (part of Sacmi Group) among the most important international players, but there are several innovations that will be presented at the fair.

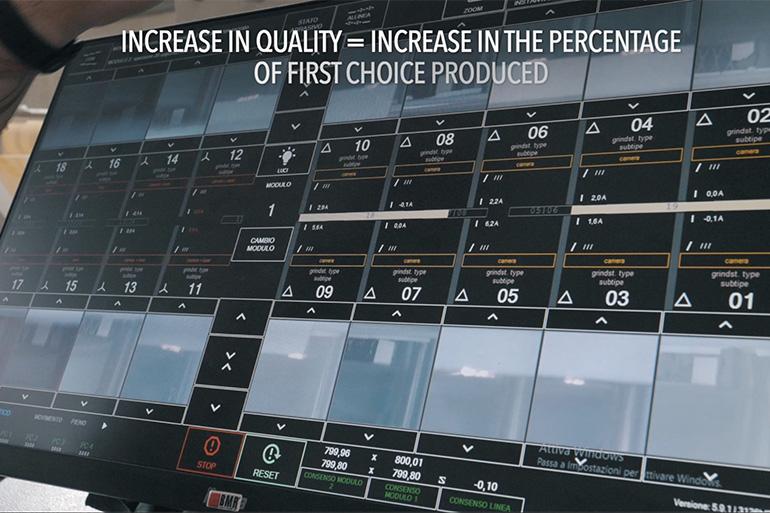

Among them, there will be the LeviCompact, an exclusive BMR patent dedicated to the lapping, satin finishing and polishing of large slabs, with a width of 1600-1800 mm, which allows more speed and uniformity compared to traditional processing, also thanks to the two parallel and swinging bridges with 10 heads each. The company will also show some ever-present evergreens, which have been renewed: ranging from an even more performing, digital and customizable Leviga to a SuperShine which features a new, more performing pumping system and a better communication process. Also present is the 4.0 version of the SquadraDry Vision, equipped with measuring cameras and a laser system to guarantee considerable benefits in terms of respect for the environment, energy saving, consumption and tool cost. In the cutting sector, BMR then presented the dry Twin-Cut machine for surface engraving with opposite pre-cut, ideal for thick materials.

The success of BMR in North America can also be attributed to the BMR USA branch which was inaugurated 6 years ago in Crossville, Tennessee, the heart of the US ceramic valley. The space today represents a real logistics hub for the supply of spare parts and support and is the result of the company’s awareness that increasingly efficient management of spare parts plays a key role in guaranteeing maximum functionality between pre- and post-sales service. With this aim of improving customer service, BMR USA has expanded the first building, with the new structure which today guarantees faster response times and copes with the growing complexity of the systems required by local ceramic tile producers and the need for a support and maintenance service.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks