Primus Ceramics installs the first zero-impact dryer in collaboration with Sacmi

With an installed power of 800 kW, the dryer can operate at full capacity using the energy from the factory’s photovoltaic roof.

Portuguese company Primus Ceramics has started up the first ceramic dryer to be 100% powered using electricity generated from renewable sources. It was built by Sacmi, a technology partner of the Aveiro-based company since 2008 when it installed a complete line with a capacity of 4 million tiles per year. Sacmi modified the existing 5-tier ECP dryer to allow it to operate at full capacity using electricity generated by the facility’s photovoltaic roof, which was completed by Primus in 2020.

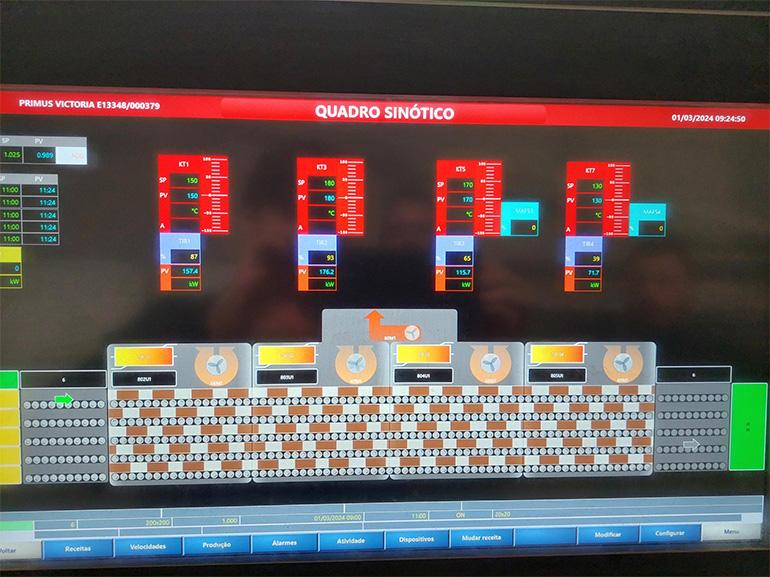

The 4 dryer modules were equipped with suitable heating elements with a total installed power of 800 kW, sufficient to run the machine at full capacity without using traditional fuel. To achieve its new sustainability targets, Primus subsequently expanded its photovoltaic roof, which now generates 2 GWh annually and avoids the release of 1,000 tons/eq of CO2 into the atmosphere each year.

The key strength of the newly configured dryer is the fact that it can operate in full electric mode, gas mode or hybrid mode (e.g. two electric modules + two gas modules) when less photovoltaic energy is available. This means that the machine is equipped to ensure continuity of production at all times. A further advantage is that the existing machine can be modified without altering the plant layout.

This solution is replicable on a large scale, and following the successful experience with Primus Ceramics allows Sacmi to offer the ceramic industry further opportunities for decarbonisation.

Did you find this article useful?

Join the CWW community to receive the most important news from the global ceramic industry every two weeks